PAGE 1 of 2 : NEXT PAGE

Biodiesel refers to a non-petroleum-based diesel fuel consisting of long-chain alkyl (methyl, propyl or ethyl) esters. Biodiesel is typically made by chemically-reacting lipids (e.g., vegetable oil, animal fat (tallow)) and alcohol. It can be used (alone, or blended with conventional petrodiesel) in unmodified diesel-engine vehicles. Biodiesel is distinguished from the straight vegetable oil (SVO) (sometimes referred to as "waste vegetable oil", "WVO", "used vegetable oil", "UVO", "pure plant oil", "PPO") used (alone, or blended) as fuels in some converted diesel vehicles. "Biodiesel" is standardized as mono-alkyl ester.[1]

|

| Bus run by biodiesel |

Blends

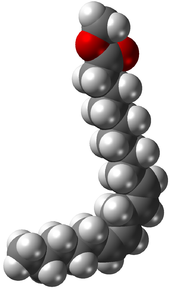

|

Space-filling model of methyl linoleate, or linoleic acid methyl ester,a common methyl ester produced from soybean or canola oil and methanol |

- Mixing in tanks at manufacturing point prior to delivery to tanker truck

- Splash mixing in the tanker truck (adding specific percentages of Biodiesel and petroleum diesel)

- In-line mixing, two components arrive at tanker truck simultaneously.

- Metered pump mixing, petroleum diesel and Biodiesel meters are set to X total volume, transfer pump pulls from two points and mix is complete on leaving pump.

Origin

|

| Space-filling model of ethyl stearate, or stearicacid ethyl ester, an ethyl ester produced from soybean or canola oil and ethanol |

On August 31, 1937, G. Chavanne of the University of Brussels (Belgium) was granted a patent for a ’Procedure for the transformation of vegetable oils for their uses as fuels’ (fr. ’Procédé de Transformation d’Huiles Végétales en Vue de Leur Utilisation comme Carburants’) Belgian Patent 422,877. This patent described the alcoholysis (often referred to as transesterification) of vegetable oils using ethanol (and mentions methanol) in order to separate the fatty acids from the glycerol by replacing the glycerol with short linear alcohols. This appears to be the first account of the production of what is known as ’biodiesel’ today.[3]

Applications

Biodiesel can be used in pure form (B100) or may be blended with petroleum diesel at any concentration in most modern diesel engines. Biodiesel has different solvent properties than petrodiesel, and will degrade natural rubber gaskets and hoses in vehicles (mostly vehicles manufactured before 1992), although these tend to wear out naturally and most likely will have already been replaced with FKM, which is nonreactive to biodiesel. Biodiesel has been known to break down deposits of residue in the fuel lines where petrodiesel has been used.[4] As a result, fuel filters may become clogged with particulates if a quick transition to pure biodiesel is made. Therefore, it is recommended to change the fuel filters on engines and heaters shortly after first switching to a biodiesel blend.[5]

Distribution

Since the passage of the Energy Policy Act of 2005 biodiesel use has been increasing in the United States.[6] In Europe, the Renewable Transport Fuel Obligation obliges suppliers to include 5% renewable fuel in all transport fuel sold in the EU by 2010. For road diesel, this effectively means 5% biodiesel. A growing number of transport fleets use it as an additive in their fuel. Biodiesel is often more expensive to purchase than petroleum diesel but this is expected to diminish due to economies of scale and agricultural subsidies versus the rising cost of petroleum as reserves are depleted.

Since the passage of the Energy Policy Act of 2005 biodiesel use has been increasing in the United States.[6] In Europe, the Renewable Transport Fuel Obligation obliges suppliers to include 5% renewable fuel in all transport fuel sold in the EU by 2010. For road diesel, this effectively means 5% biodiesel. A growing number of transport fleets use it as an additive in their fuel. Biodiesel is often more expensive to purchase than petroleum diesel but this is expected to diminish due to economies of scale and agricultural subsidies versus the rising cost of petroleum as reserves are depleted.

Vehicular use and manufacturer acceptance

In 2005, Chrysler (then part of Daimler-Chrysler) released the Jeep Liberty CRD diesels from the factory into the American market with 5% biodiesel blends, indicating at least partial acceptance of biodiesel as an acceptable diesel fuel additive.[7] In 2007, DaimlerChrysler indicated intention to increase warranty coverage to 20% biodiesel blends if biofuel quality in the United States can be standardized.[8]

In 2005, Chrysler (then part of Daimler-Chrysler) released the Jeep Liberty CRD diesels from the factory into the American market with 5% biodiesel blends, indicating at least partial acceptance of biodiesel as an acceptable diesel fuel additive.[7] In 2007, DaimlerChrysler indicated intention to increase warranty coverage to 20% biodiesel blends if biofuel quality in the United States can be standardized.[8]

Railway usage

The British businessman Richard Branson’sVirgin Voyager train, number 220007 Thames Voyager,[9] billed as the world’s first "biodiesel train" was converted to run on 80% petrodiesel and only 20% biodiesel, and it is claimed it will save 14% on direct emissions. Similarly, a state-owned short-line railroad in Eastern Washington ran a test of a 25% biodiesel/75% petrodiesel blend during the summer of 2008, purchasing fuel from a biodiesel producer seated along the railroad tracks.[10] The train will be powered by biodiesel made in part from canola grown in agricultural regions through which the short line runs. Also in 2007 Disneyland began running the park trains on B98 biodiesel blends (98% biodiesel). The program blipped in 2008 due to storage issues, but in January 2009 it was announced that they are now running all the trains on biodiesel manufactured locally from used cooking oils from the park. This is a change from running the trains on soy based biodiesel.[11]

|

| Biodiesel sample |

Aircraft use

Aircraft manufacturers are even more cautious due to the inherent risks of air travel, but a test flight has been performed by a Czech Aircraft (completely powered on biofuel);[12] testing has been announced by Rolls Royce plc, Air New Zealand and Boeing (one engine out of four on a Boeing 747);[13] and commercial passenger jet testing has also been announced[14] by Virgin Atlantic’s Richard Branson. The world’s first biofuel-powered commercial aircraft took off from London’s Heathrow Airport on February 24, 2008 and touched down in Amsterdam on a demonstration flight hailed as a first step towards "cleaner" flying. The "BioJet" fuel for this flight was produced by Seattle based Imperium Renewables, Inc.[15] See also Air travel, climate change, and green consumerism.

Aircraft manufacturers are even more cautious due to the inherent risks of air travel, but a test flight has been performed by a Czech Aircraft (completely powered on biofuel);[12] testing has been announced by Rolls Royce plc, Air New Zealand and Boeing (one engine out of four on a Boeing 747);[13] and commercial passenger jet testing has also been announced[14] by Virgin Atlantic’s Richard Branson. The world’s first biofuel-powered commercial aircraft took off from London’s Heathrow Airport on February 24, 2008 and touched down in Amsterdam on a demonstration flight hailed as a first step towards "cleaner" flying. The "BioJet" fuel for this flight was produced by Seattle based Imperium Renewables, Inc.[15] See also Air travel, climate change, and green consumerism.

As a heating oil

Biodiesel can also be used as a heating fuel in domestic and commercial boilers, sometimes known as bioheat. Older furnaces may contain rubber parts that would be affected by biodiesel’s solvent properties, but can otherwise burn biodiesel without any conversion required. Care must be taken at first, however, given that varnishes left behind by petrodiesel will be released and can clog pipes-fuel filtering and prompt filter replacement is required. Another approach is to start using biodiesel as blend, and decreasing the petroleum proportion over time can allow the varnishes to come off more gradually and be less likely to clog. Thanks to its strong solvent properties, however, the furnace is cleaned out and generally becomes more efficient. A technical research paper[16] describes laboratory research and field trials project using pure biodiesel and biodiesel blends as a heating fuel in oil fired boilers. During the Biodiesel Expo 2006 in the UK, Andrew J. Robertson presented his biodiesel heating oil research from his technical paper and suggested that B20 biodiesel could reduce UK household CO2 emissions by 1.5 million tons per year.

Biodiesel can also be used as a heating fuel in domestic and commercial boilers, sometimes known as bioheat. Older furnaces may contain rubber parts that would be affected by biodiesel’s solvent properties, but can otherwise burn biodiesel without any conversion required. Care must be taken at first, however, given that varnishes left behind by petrodiesel will be released and can clog pipes-fuel filtering and prompt filter replacement is required. Another approach is to start using biodiesel as blend, and decreasing the petroleum proportion over time can allow the varnishes to come off more gradually and be less likely to clog. Thanks to its strong solvent properties, however, the furnace is cleaned out and generally becomes more efficient. A technical research paper[16] describes laboratory research and field trials project using pure biodiesel and biodiesel blends as a heating fuel in oil fired boilers. During the Biodiesel Expo 2006 in the UK, Andrew J. Robertson presented his biodiesel heating oil research from his technical paper and suggested that B20 biodiesel could reduce UK household CO2 emissions by 1.5 million tons per year.

Historical background

Transesterification of a vegetable oil was conducted as early as 1853 by scientists E. Duffy and J. Patrick, many years before the first diesel engine became functional. Rudolf Diesel’s prime model, a single 10 ft (3 m) iron cylinder with a flywheel at its base, ran on its own power for the first time in Augsburg, Germany, on August 10, 1893. In remembrance of this event, August 10 has been declared "International Biodiesel Day".

The French Otto Company (at the request of the French government) demonstrated a Diesel engine running on peanut oil at the World Fair in Paris, France in 1900, where it received the Grand Prix (highest prize).[17]

This engine stood as an example of Diesel’s vision because it was powered by peanut oil --- a biofuel, though not biodiesel, since it was not transesterified. He believed that the utilization of biomass fuel was the real future of his engine. In a 1912 speech Diesel said, "the use of vegetable oils for engine fuels may seem insignificant today but such oils may become, in the course of time, as important as petroleum and the coal-tar products of the present time."

During the 1920s, diesel engine manufacturers altered their engines to utilize the lower viscosity of petrodiesel (a fossil fuel), rather than vegetable oil (a biomass fuel). The petroleum industries were able to make inroads in fuel markets because their fuel was much cheaper to produce than the biomass alternatives. The result, for many years, was a near elimination of the biomass fuel production infrastructure. Only recently, have environmental impact concerns and a decreasing price differential made biomass fuels such as biodiesel a growing alternative.

Despite the widespread use of fossil petroleum-derived diesel fuels, interest in vegetable oils as fuels in internal combustion engines is reported in several countries during the 1920s and 1930’s and later during World War II. Belgium, France, Italy, the United Kingdom, Portugal, Germany, Brazil, Argentina, Japan and China have been reported to have tested and used vegetable oils as diesel fuels during this time. Some operational problems were reported due to the high viscosity of vegetable oils compared to petroleum diesel fuel, which result in poor atomization of the fuel in the fuel spray and often leads to deposits and coking of the injectors, combustion chamber and valves. Attempts to overcome these problems included heating of the vegetable oil, blending it with petroleumderived diesel fuel or ethanol, pyrolysis and cracking of the oils.

On August 31, 1937, G. Chavanne of the University of Brussels (Belgium) was granted a patent for a "Procedure for the transformation of vegetable oils for their uses as fuels" (fr. ’Procédé de Transformation d’Huiles Végétales en Vue de Leur Utilisation comme Carburants’) Belgian Patent 422,877. This patent described the alcoholysis (often referred to as transesterification) of vegetable oils using methanol and ethanol in order to separate the fatty acids from the glycerol by replacing the glycerol by short linear alcohols. This appears to be the first account of the production of what is known as "biodiesel" today.

More recently, in 1977, Brazilian scientist Expedito Parente invented and submitted for patent, the first industrial process for the production of biodiesel.[18] This process is classified as biodiesel by international norms, conferring a "standardized identity and quality. No other proposed biofuel has been validated by the motor industry."[19] Currently, Parente’s company Tecbio is working with Boeing and NASA to certify bioquerosene (bio-kerosene), another product produced and patented by the Brazilian scientist.[20]

Research into the use of transesterified sunflower oil, and refining it to diesel fuel standards, was initiated in South Africa in 1979. By 1983, the process for producing fuel-quality, engine-tested biodiesel was completed and published internationally.[21] An Austrian company, Gaskoks, obtained the technology from the South African Agricultural Engineers; the company erected the first biodiesel pilot plant in November 1987, and the first industrial-scale plant in April 1989 (with a capacity of 30,000 tons of rapeseed per annum).

Throughout the 1990s, plants were opened in many European countries, including the Czech Republic, Germany and Sweden. France launched local production of biodiesel fuel (referred to as diester) from rapeseed oil, which is mixed into regular diesel fuel at a level of 5%, and into the diesel fuel used by some captive fleets (e.g. public transportation) at a level of 30%. Renault, Peugeot and other manufacturers have certified truck engines for use with up to that level of partial biodiesel; experiments with 50% biodiesel are underway. During the same period, nations in other parts of the world also saw local production of biodiesel starting up: by 1998, the Austrian Biofuels Institute had identified 21 countries with commercial biodiesel projects. 100% Biodiesel is now available at many normal service stations across Europe.

In September 2005 Minnesota became the first U.S. state to mandate that all diesel fuel sold in the state contain part biodiesel, requiring a content of at least 2% biodiesel.[22] In 2008, ASTM published new Biodiesel Blend Specifications Standards.[23] These biodiesel standards can be accessed via a web-based application.[24]

Properties

Biodiesel has better lubricating properties and much higher cetane ratings than today’s lower sulfur diesel fuels. Biodiesel addition reduces fuel system wear,[25] and in low levels in high pressure systems increases the life of the fuel injection equipment that relies on the fuel for its lubrication. Depending on the engine, this might include high pressure injection pumps, pump injectors (also called unit injectors) and fuel injectors.

|

Older diesel Mercedes are popular for running on biodiesel |

Biodiesel is a liquid which varies in color --- between golden and dark brown --- depending on the production feedstock. It is immiscible with water, has a high boiling point and low vapor pressure. *The flash point of biodiesel (>130 °C, >266 °F)[29] is significantly higher than that of petroleum diesel (64 °C, 147 °F) or gasoline (−45 °C, -52 °F). Biodiesel has a density of ~ 0.88 g/cm³, less than that of water. Biodiesel has virtually no sulfur content, and it is often used as an additive to Ultra-Low Sulfur Diesel (ULSD) fuel.

Material compatibility

- Plastics: High density polyethylene is compatible but PVC is slowly degraded. Polystyrenes are dissolved on contact with biodiesel.

- Metals: Biodiesel has an effect on copperbased materials (e.g. brass), and it also affects zinc, tin, lead, and cast iron. Stainless steels (316 and 304) and aluminum are unaffected.

- Rubber: Biodiesel also affects types of natural rubbers found in some older engine components. Studies have also found that fluorinated elastomers (FKM) cured with peroxide and base-metal oxides can be degraded when biodiesel loses its stability caused by oxidation. However testing with FKM- GBL-S and FKM- GF-S were found to be the toughest elastomer to handle biodiesel in all conditions.

Technical standards

Biodiesel has a number of standards for its quality including European standard EN 14214, ASTM International D6751, and others.

Gelling

The cloud point, or temperature at which pure (B100) biodiesel starts to gel, varies significantly and depends upon the mix of esters and therefore the feedstock oil used to produce the biodiesel. For example, biodiesel produced from low erucic acid varieties of canola seed (RME) starts to gel at approximately -10 °C (14 °F). Biodiesel produced from tallow tends to gel at around +16 °C (61 °F). As of 2006, there are a very limited number of products that will significantly lower the gel point of straight biodiesel. A number of studies have shown that winter operation is possible with biodiesel blended with other fuel oils including #2 low sulfur diesel fuel and #1 diesel / kerosene. The exact blend depends on the operating environment: successful operations have run using a 65% LS #2, 30% K #1, and 5% bio blend. Other areas have run a 70% Low Sulfur #2, 20% Kerosene #1, and 10% bio blend or an 80% K#1, and 20% biodiesel blend. According to the National Biodiesel Board (NBB), B20 (20% biodiesel, 80% petrodiesel) does not need any treatment in addition to what is already taken with petrodiesel.

To permit the use of biodiesel without mixing and without the possibility of gelling at low temperatures, some people modify their vehicles with a second fuel tank for biodiesel in addition to the standard fuel tank. Alternately, a vehicle with two tanks is chosen. The second fuel tank is insulated and a heating coil using engine coolant is run through the tank. When a temperature sensor indicates that the fuel is warm enough to burn, the driver switches from the petrodiesel tank to the biodiesel tank. This is similar to the method used for running straight vegetable oil.

Contamination by water

Biodiesel may contain small but problematic quantities of water. Although it is not miscible with water, it is, like ethanol, hygroscopic (absorbs water from atmospheric moisture).[30] One of the reasons biodiesel can absorb water is the persistence of mono and diglycerides left over from an incomplete reaction. These molecules can act as an emulsifier, allowing water to mix with the biodiesel. In addition, there may be water that is residual to processing or resulting from storage tank condensation. The presence of water is a problem because:

- Water reduces the heat of combustion of the bulk fuel. This means more smoke, harder starting, less power.

- Water causes corrosion of vital fuel system components: fuel pumps, injector pumps, fuel lines, etc.

- Water & microbes cause the paper element filters in the system to fail (rot), which in turn results in premature failure of the fuel pump due to ingestion of large particles.

- Water freezes to form ice crystals near 0 °C (32 °F). These crystals provide sites for nucleation and accelerate the gelling of the residual fuel.

- Water accelerates the growth of microbe colonies, which can plug up a fuel system. Biodiesel users who have heated fuel tanks therefore face a year-round microbe problem.

- Additionally, water can cause pitting in the pistons on a diesel engine.

Previously, the amount of water contaminating biodiesel has been difficult to measure by taking samples, since water and oil separate. However, it is now possible to measure the water content using water-in-oil sensors.

Water contamination is also a potential problem when using certain chemical catalysts involved in the production process, substantially reducing catalytic efficiency of base (high pH) catalysts such as potassium hydroxide. However, the super-critical methanol production methodology, whereby the transesterification process of oil feedstock and methanol is effectuated under high temperature and pressure, has been shown to be largely unaffected by the presence of water contamination during the production phase.

Availability and prices

For more details on this topic, see Biodiesel around the world.

Global biodiesel production reached 3.8 million tons in 2005. Approximately 85% of biodiesel production came from the European Union.

In the United States, average retail (at the pump) prices, including Federal and state fuel taxes, of B2/B5 are lower than petroleum diesel by about 12 cents, and B20 blends are the same as petrodiesel.[31] B99 and B100 generally cost more than petrodiesel except where local governments provide a subsidy.

Production

For more details on this topic, see Biodiesel production.

Biodiesel is commonly produced by the transesterification of the vegetable oil or animal fat feedstock. There are several methods for carrying out this transesterification reaction including the common batch process, supercritical processes, ultrasonic methods, and even microwave methods.

|

In some countries biodiesel is less expensive than conventional diesel |

A lipid transesterification production process is used to convert the base oil to the desired esters. Any Free fatty acids (FFAs) in the base oil are either converted to soap and removed from the process, or they are esterified (yielding more biodiesel) using an acidic catalyst. After this processing, unlike straight vegetable oil, biodiesel has combustion properties very similar to those of petroleum diesel, and can replace it in most current uses.

A by-product of the transesterification process is the production of glycerol. For every 1 ton of biodiesel that is manufactured, 100 kg of glycerol are produced. Originally, there was a valuable market for the glycerol, which assisted the economics of the process as a whole. However, with the increase in global biodiesel production, the market price for this crude glycerol (containing 20% water and catalyst residues) has crashed. Research is being conducted globally to use this glycerol as a chemical building block. One initiative in the UK is The Glycerol Challenge.[32]

|

Soybeans are used as a source of biodiesel |

Production levels

For more details on this topic, see Biodiesel around the world.

For more details on this topic, see Biodiesel around the world.

Biodiesel production capacity is growing rapidly, with an average annual growth rate from 2002-2006 of over 40%.[36] For the year 2006, the latest for which actual production figures could be obtained, total world biodiesel production was about 5-6 million tonnes, with 4.9 million tonnes processed in Europe (of which 2.7 million tonnes was from Germany) and most of the rest from the USA.[37]. In 2007 production in Europe alone had risen to 5.7 million tonnes.[38] The capacity for 2008 in Europe totalled 16 million tonnes. This compares with a total demand for diesel in the US and Europe of approximately 490 million tonnes (147 billion gallons).[39] Total world production of vegetable oil for all purposes in 2005/06 was about 110 million tonnes, with about 34 million tonnes each of palm oil and soybean oil.[40]

Biodiesel feedstocks

A variety of oils can be used to produce biodiesel. These include:

A variety of oils can be used to produce biodiesel. These include:

- Virgin oil feedstock; rapeseed and soybean oils are most commonly used, soybean oil alone accounting for about ninety percent of all fuel stocks in the US. It also can be obtained from field pennycress and Jatropha other crops such as mustard, flax, sunflower, palm oil, hemp (see List of vegetable oils for a more complete list);

- Waste vegetable oil (WVO);

- Animal fats including tallow, lard, yellow grease, chicken fat,[41] and the byproducts of the production of Omega-3 fatty acids from fish oil.

- Algae, which can be grown using waste materials such as sewage[42] and without displacing land currently used for food production.

- Oil from halophytes such as salicornia bigelovii, which can be grown using saltwater in coastal areas where conventional crops cannot be grown, with yields equal to the yields of soybeans and other oilseeds grown using freshwater irrigation[43]

Many advocates suggest that waste vegetable oil is the best source of oil to produce biodiesel, but since the available supply is drastically less than the amount of petroleum-based fuel that is burned for transportation and home heating in the world, this local solution does not scale well.

Animal fats are a by-product of meat production. Although it would not be efficient to raise animals (or catch fish) simply for their fat, use of the by-product adds value to the livestock industry (hogs, cattle, poultry). However, producing biodiesel with animal fat that would have otherwise been discarded could replace a small percentage of petroleum diesel usage. Today, multi-feedstock biodiesel facilities are producing high quality animal-fat based biodiesel. Currently, a 5-million dollar plant is being built in the USA, with the intent of producing 11.4 million litres (3 million gallons) biodiesel from some of the estimated 1 billion kg (2.3 billion pounds) of chicken fat[44] produced annually the local Tyson poultry plant.[41] Similarly, some small-scale biodiesel factories use waste fish oil as feedstock.[45][46]

Quantity of feedstocks required

Worldwide production of vegetable oil and animal fat is not sufficient to replace liquid fossil fuel use. Furthermore, some object to the vast amount of farming and the resulting fertilization, pesticide use, and land use conversion that would be needed to produce the additional vegetable oil. The estimated transportation diesel fuel and home heating oil used in the United States is about 160 million tonnes (350 billion pounds) according to the Energy Information Administration, US Department of Energy -.[47] In the United States, estimated production of vegetable oil for all uses is about 11 million tonnes (24 billion pounds) and estimated production of animal fat is 5.3 million tonnes (12 billion pounds).[48]

Worldwide production of vegetable oil and animal fat is not sufficient to replace liquid fossil fuel use. Furthermore, some object to the vast amount of farming and the resulting fertilization, pesticide use, and land use conversion that would be needed to produce the additional vegetable oil. The estimated transportation diesel fuel and home heating oil used in the United States is about 160 million tonnes (350 billion pounds) according to the Energy Information Administration, US Department of Energy -.[47] In the United States, estimated production of vegetable oil for all uses is about 11 million tonnes (24 billion pounds) and estimated production of animal fat is 5.3 million tonnes (12 billion pounds).[48]

If the entire arable land area of the USA (470 million acres, or 1.9 million square kilometers) were devoted to biodiesel production from soy, this would just about provide the 160 million tonnes required (assuming an optimistic 98 GPa of biodiesel). This land area could in principle be reduced significantly using algae, if the obstacles can be overcome. The US DOE estimates that if algae fuel replaced all the petroleum fuel in the United States, it would require 15,000 square miles (38,849 square kilometers), which is a few thousand square miles larger than Maryland, or 1.3 Belgiums,[49][50] assuming a yield of 140 tonnes/hectare (15,000 GPa). Given a more realistic yield of 36 tonnes/hectare (3834 GPa) the area required is about 152,000 square kilometers, or roughly equal to that of the state of Georgia or England and Wales. The advantages of algae are that it can be grown on non-arable land such as deserts or in marine environments, and the potential oil yields are much higher than from plants.

Yield

Feedstock yield efficiency per acre affects the feasibility of ramping up production to the huge industrial levels required to power a significant percentage of national or world vehicles. Some typical yields in cubic decimeters (liters) of biodiesel per hectare (10,000 square meters):

Feedstock yield efficiency per acre affects the feasibility of ramping up production to the huge industrial levels required to power a significant percentage of national or world vehicles. Some typical yields in cubic decimeters (liters) of biodiesel per hectare (10,000 square meters):

- Algae: 2763 dm3 (liter) or more (~300 gallons per acre; est.- see soy figures and DOE quote below)

- Hemp: 1535 dm3[51]

- Chinese tallow: 772 dm3[52] - 970 GPa[53]

- Palm oil: 780 - 1490 dm3 [54]

- Coconut: 353 dm3[54]

- Rapeseed: 157 dm3[54]

- Soy: 76-161 dm3 in Indiana[55]

- Peanut: 138 dm3[54]

- Sunflower: 126 dm3[54]

Algae fuel yields have not yet been accurately determined, but DOE is reported as saying that algae yield 30 times more energy per acre than land crops such as soybeans.[56] Yields of 36 tonnes/hectare are considered practical by Ami Ben-Amotz of the Institute of Oceanography in Haifa, who has been farming Algae commercially for over 20 years.[57]

The Jatropha plant has been cited as a high-yield source of biodiesel but yields are highly dependent on climatic and soil conditions. The estimates at the low end put the yield at about 200 GPa (1.5-2 tonnes per hectare) per crop; in more favorable climates two or more crops per year have been achieved.[58] It is grown in the Philippines, Mali and India, is drought-resistant, and can share space with other cash crops such as coffee, sugar, fruits and vegetables.[59] It is well-suited to semi-arid lands and can contribute to slow down desertification, according to its advocates.[60]

Efficiency and economic arguments

According to a study by Drs. Van Dyne and Raymer for the Tennessee Valley Authority, the average US farm consumes fuel at the rate of 82 litres per hectare (8.75 US gallons per acre) of land to produce one crop. However, average crops of rapeseed produce oil at an average rate of 1,029 L/ha (110 US gal/acre), and high-yield rapeseed fields produce about 1,356 L/ha (145 US gal/acre). The ratio of input to output in these cases is roughly 1:12.5 and 1:16.5. Photosynthesis is known to have an efficiency rate of about 3-6% of total solar radiation[61] and if the entire mass of a crop is utilized for energy production, the overall efficiency of this chain is currently about 1%[62] While this may compare unfavorably to solar cells combined with an electric drive train, biodiesel is less costly to deploy (solar cells cost approximately US$1,000 per square meter) and transport (electric vehicles require batteries which currently have a much lower energy density than liquid fuels).

According to a study by Drs. Van Dyne and Raymer for the Tennessee Valley Authority, the average US farm consumes fuel at the rate of 82 litres per hectare (8.75 US gallons per acre) of land to produce one crop. However, average crops of rapeseed produce oil at an average rate of 1,029 L/ha (110 US gal/acre), and high-yield rapeseed fields produce about 1,356 L/ha (145 US gal/acre). The ratio of input to output in these cases is roughly 1:12.5 and 1:16.5. Photosynthesis is known to have an efficiency rate of about 3-6% of total solar radiation[61] and if the entire mass of a crop is utilized for energy production, the overall efficiency of this chain is currently about 1%[62] While this may compare unfavorably to solar cells combined with an electric drive train, biodiesel is less costly to deploy (solar cells cost approximately US$1,000 per square meter) and transport (electric vehicles require batteries which currently have a much lower energy density than liquid fuels).

However, these statistics by themselves are not enough to show whether such a change makes economic sense. Additional factors must be taken into account, such as: the fuel equivalent of the energy required for processing, the yield of fuel from raw oil, the return on cultivating food, the effect biodiesel will have on food prices and the relative cost of biodiesel versus petrodiesel.

The debate over the energy balance of biodiesel is ongoing. Transitioning fully to biofuels could require immense tracts of land if traditional food crops are used (although non food crops can be utilized). The problem would be especially severe for nations with large economies, since energy consumption scales with economic output.[63]

If using only traditional food plants, most such nations do not have sufficient arable land to produce biofuel for the nation’s vehicles. Nations with smaller economies (hence less energy consumption) and more arable land may be in better situations, although many regions cannot afford to divert land away from food production.

For third world countries, biodiesel sources that use marginal land could make more sense, e.g. honge oil nuts[64] grown along roads or jatropha grown along rail lines.In tropical regions, such as Malaysia and Indonesia, oil palm is being planted at a rapid pace to supply growing biodiesel demand in Europe and other markets. It has been estimated in Germany that palm oil biodiesel has less than 1/3 the production costs of rapeseed biodiesel.[65] The direct source of the energy content of biodiesel is solar energy captured by plants during photosynthesis. Regarding the positive energy balance of biodiesel: When straw was left in the field, biodiesel production was strongly energy positive, yielding 1 GJ biodiesel for every 0.561 GJ of energy input (a yield/cost ratio of 1.78).

When straw was burned as fuel and oilseed rapemeal was used as a fertilizer, the yield/cost ratio for biodiesel production was even better (3.71). In other words, for every unit of energy

input to produce biodiesel, the output was 3.71 units (the difference of 2.71 units would be from solar energy).

Biodiesel is becoming of interest to companies interested in commercial scale production as well as the more usual home brew biodiesel user and the user of straight vegetable oil or waste vegetable oil in diesel engines. Homemade biodiesel processors are many and varied.

Retrieved from : Wikipedia

PAGE 1 of 2 : NEXT PAGE

No comments:

Post a Comment